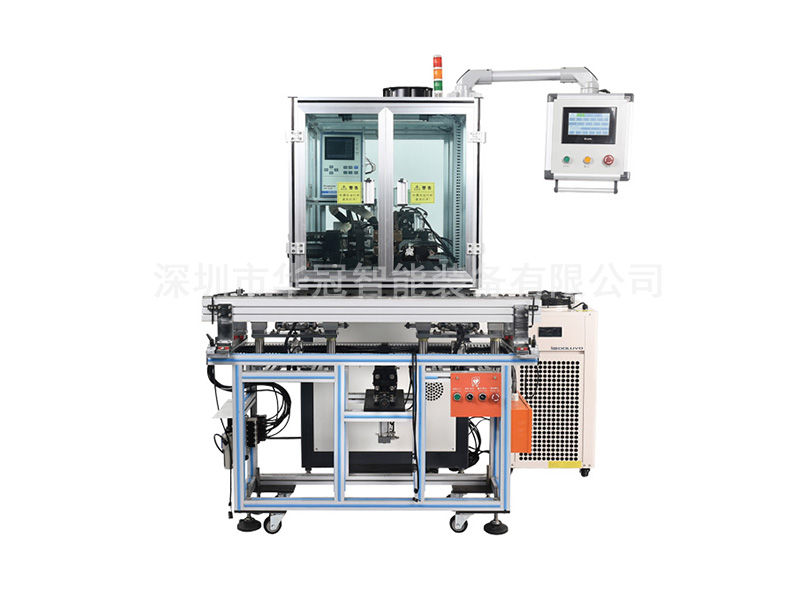

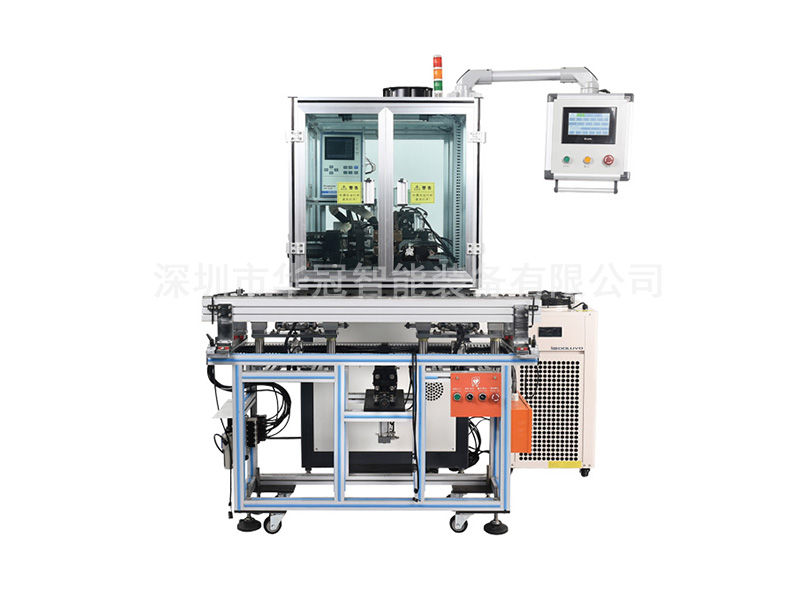

Rotor commutator single/double had spot welding machine HG-H41/H51

Major technical parameters:

Feeding method: Sawtooth feed

Indexing method: Servo indexing, can randomly set the angle of distribution between each hook foot on a workpiece and perform spot welding.

Parameter settings: touch screen settings and power parameter settings.

Control power supply: closed-loop feedback, high precision inverter

Applicable commutator type: hook type

Single hook beat: depending on rotor size, welding requirements, about 1~2S/hook.

Enameled wire diameter: φ0.15mm-φ2.0 mm (only for standard machines, please specify special requirements)

Rotor outside diameter: φ20 mm-φ62 mm (only for standard machines, please specify special requirements)

Commutator diameter: ≦ 40 mm (standard machine only, please specify special requirements)

Rotary shaft diameter: φ3 mm-φ15 mm (standard machine only, please specify special requirements)

Number of commutator hooks/slots: 3 to 36 hooks (For standard machines only, please specify special requirements)

Cooling method: chiller

Compressed air: 0.4MPa-0.6MPa

Equipment power supply: three-phase AC380V±10% 50HZ 40KW

Total weight: ≤800kg

Service hotline: 0755-23468502 / 27155162

Functions and features

H41 is a horizontal spot welder, for special welding equipment for large commutator rough hooks of micro-motor rotors such as power tools

H51 is a vertical spot welding machine. It is suitable for special welding equipment for commutator hooks of micro-motor rotors for automotive motors, household appliances, etc.

Equipment welding high quality, high efficiency, environmental protection and safety

Full Chinese display, clear and accurate data and easy to operate

Preset 10 sets of welding specifications for easy recall

Will not damage insulation or deformation

With an external chiller to cool the electrode in time

Can be used stand-alone or with automatic lines